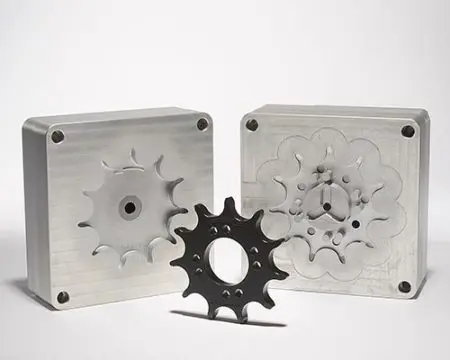

We build all customer injection molds in-house right here in Michigan. Our mold builds carry an unlimited tooling life warranty as long as we are running your production parts. All tooling is maintained by our plastic injection molding staff for the life of your project.

No matter how complex or dimensionally critical your component is, we can help you reduce design risks and limit your overall production costs with our prototyping service. Before building an expensive multi-cavity mold for your long-term production, we’ll build you a low-cost injection mold and produce low-volume production quantities for testing.

MSI Mold specializes in production quantities of 1,000 to 100,000 parts or assemblies per year. With every production injection molding project we collaborate closely with our customers on manufacturing feasibility and advanced quality planning (AQP) for reliable high-quality molding services.

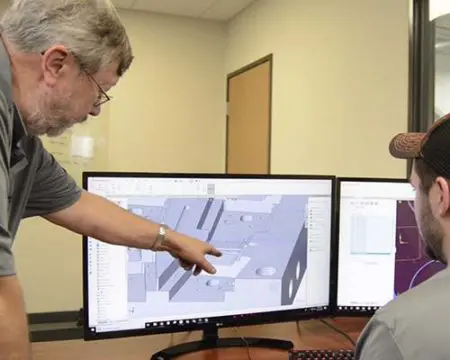

Our design team can help you bring a product concept to life. We can take your 2D drawings or sketches and create a 3D CAD model for use in rapid prototyping or production manufacturing. All part design advice or CAD model revisions are free to our customers.

We know that every project is different. If your injection molding project requires extras, including assembly, special packaging, secondary machining, or pad printing, we can accommodate your needs.

Plastic injection molding is an efficient manufacturing process that produces high-precision parts that are cost-effective, durable, and strong. The ability to repeatedly manufacture complex parts with unique geometries in a fraction of the time compared to other manufacturing processes means customers get parts faster at lower costs.

Additionally, the production runs that use a single-cavity typically require just a single operator on the molding machine. This reduces the labor costs per unit manufactured or molded. Additional benefits include making the same part with fewer defects, less waste, and faster turnaround times.

Injection molded parts have infinite applications within the industrial, commercial, residential, and consumer markets. From concept and design to prototypes and large-scale production, plastic molded components are everywhere.

We manufacture injection molded components for machinery and equipment, consumer markets, material handling, marine, oil and gas, transportation, and sports markets, to name a few.

Our commitment to providing high-quality injection molding services encompasses everything we do. The ability to do everything in-house guarantees that every aspect of your project falls under our strict quality control processes and procedures.

We prioritize customer communication and advanced quality planning on every new project. Our quality system for every project is flexible and customized to our customer needs.

All customer tooling is always made in-house, right here in the United States. We back up the quality of our molds with lifetime warranties. All of our injection molded products are made from prime-grade plastic, and we eliminate waste through our lean manufacturing processes. We manufacture your parts with clean highly efficient machinery.