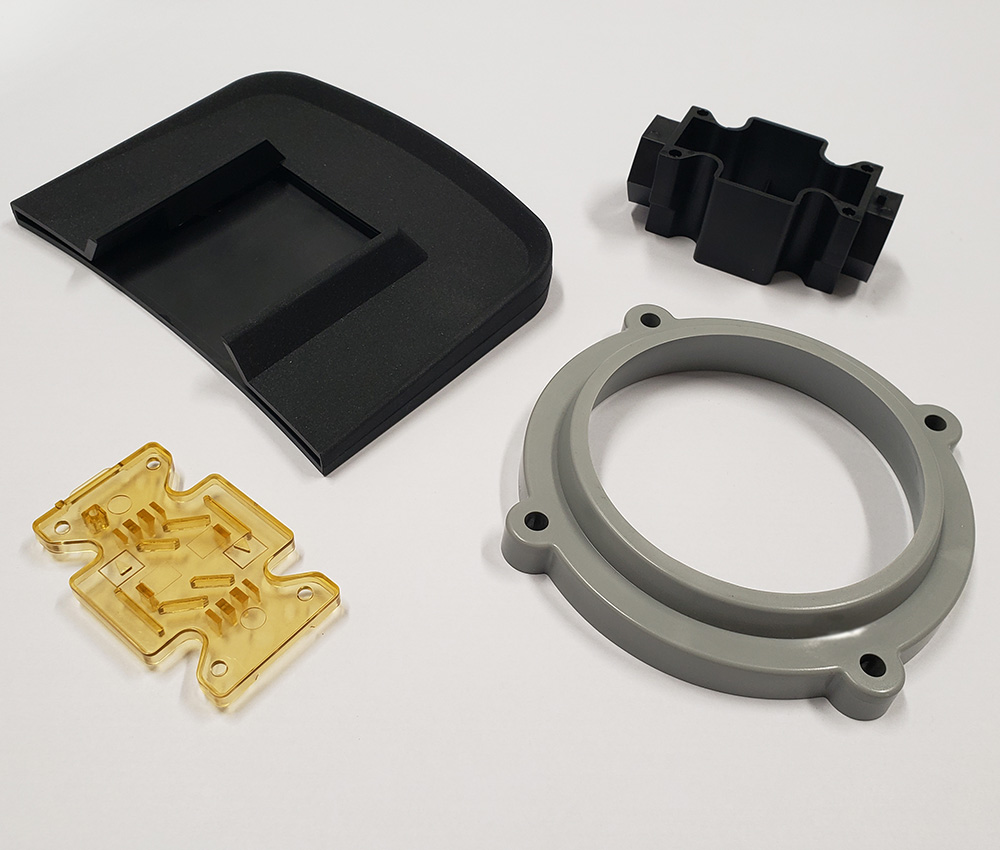

Our rich experience as a USA plastic injection molding company includes production capabilities for many different industries, plastic materials, and specialty add-ons for your custom plastic parts.

Our focus is on production runs of 100 to 100,000 units per order. We know every custom injection molding project is different, but every MSI Mold customer enjoys our key values:

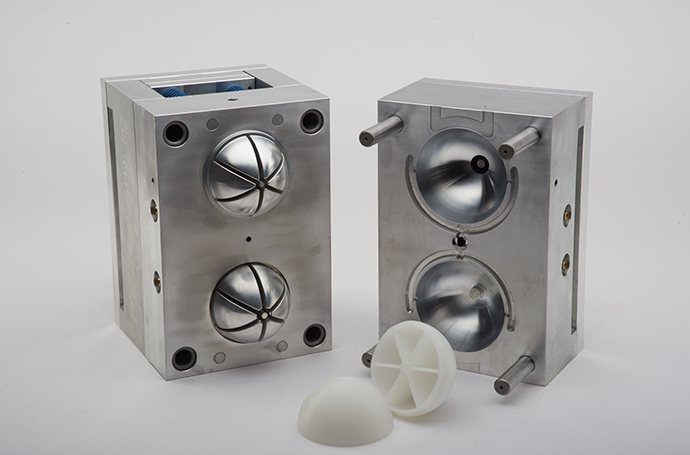

Receiving high-quality injection molded parts starts with a quality built mold. Molds for plastic injection require a significant investment so we’ll work with you every step of the way to ensure you’re familiar with the different types of molds that are available for your project. We’ll make sure you’re completely informed before you invest in your tooling. Below we provide you with a valuable understanding of basic injection mold construction types and the benefits of each.

Two of the biggest challenges with plastic injection molding projects are the cost and lead time. At MSI Mold, we overcome these challenges by building all injection molds in-house. We have also developed rapid tooling systems that reduce costs and improve lead times without sacrificing quality.

Having your mold and injection molded parts made in the United States can offer consistent quality and lower overall costs. Modern USA plastic injection molding companies use high-tech equipment and offer reliable technical expertise. In addition, if you source your project to a reputable USA injection molding supplier they will consistently use high-quality materials unlike many offshore suppliers.

When you source injection molding suppliers in the USA, you significantly lower transportation expenses and have readily available access to customer service and communication. Interaction with our injection molding experts throughout the process ensures a seamless sourcing experience production of the best possible molded plastic parts.

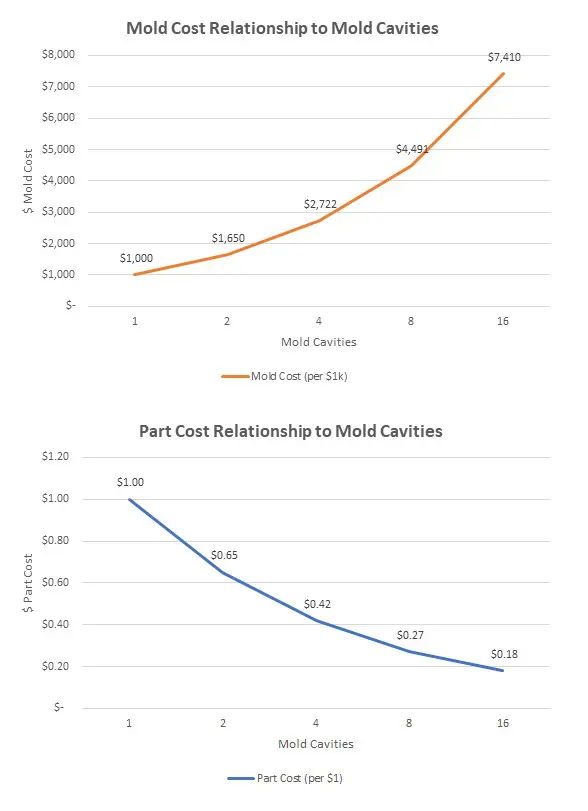

The cost of custom plastic injection molding projects for long-term production varies greatly. Simple mold tooling may range anywhere from $3,000 to $10,000. More complex, multi-cavity or high-production injection molds cost significantly more, from tens of thousands to hundreds of thousands of dollars. As explained in our cost relationship graph below, there is an inverse relationship between tooling costs and production part costs. Calculating the total cost for tooling and injection molded part prices involves assessing many factors, such as:

Computer-aided design software allows the manufacturer to take a simple 2D drawing and create an optimized 3D CAD model for your custom parts and injection molds. Our knowledgeable and friendly injection molding experts put their expertise to work with high-tech design and simulation software. We always use the latest software technologies available to reduce lead times, unexpected quality problems, and overall costs for our customers.

In-house mold manufacturing is a very important capability for injection molding companies to have. Manufacturers and buyers searching for injection molding suppliers can benefit greatly on tooling cost, lead times, and single source responsibility for overall quality by only working with suppliers that manufacture customer molds in-house and in the USA.

At MSI we have a full-service mold manufacturing area inside our facility. We control every step of our customer mold builds to prevent loss of time and unexpected quality problems.

At MSI Mold, all of our injection molding machinery is modern all-electric servo driven. That means our machines use 50-70% less energy than traditional hydraulic pump motor driven molding machinery of the past. We are proud to say that in addition to being environmentally and workplace cleaner, our machinery is the most precise and repeatable that is available in our industry.