All of MSI customer molds are built right here inside of our Michigan facility. Our mold build area is staffed with experienced designers and machinists using the most modern software and CNC machinery. After customer part designs are finalized and approved for manufacturing our team will design and build robust trouble free plastic injection molds for your production.

High-quality plastic parts start with a quality built injection mold. The mold for your custom parts can be a big investment, so we’ll work with you every step of the way to ensure you’re familiar with the different types of molds for plastic injection that are available, and we’ll make sure you’re completely informed before you invest. Below we provide you with a valuable understanding of basic injection mold construction types and the benefits of each.

This process involves using a copper or graphite electrode to electrically burn the specified mold shape into the mold component. EDM machining is slower and more costly than CNC machining, and it is only used for mold features that are not practical to cut with a CNC machine, such as sharp corners and very thin rib features. The steps of this method include:

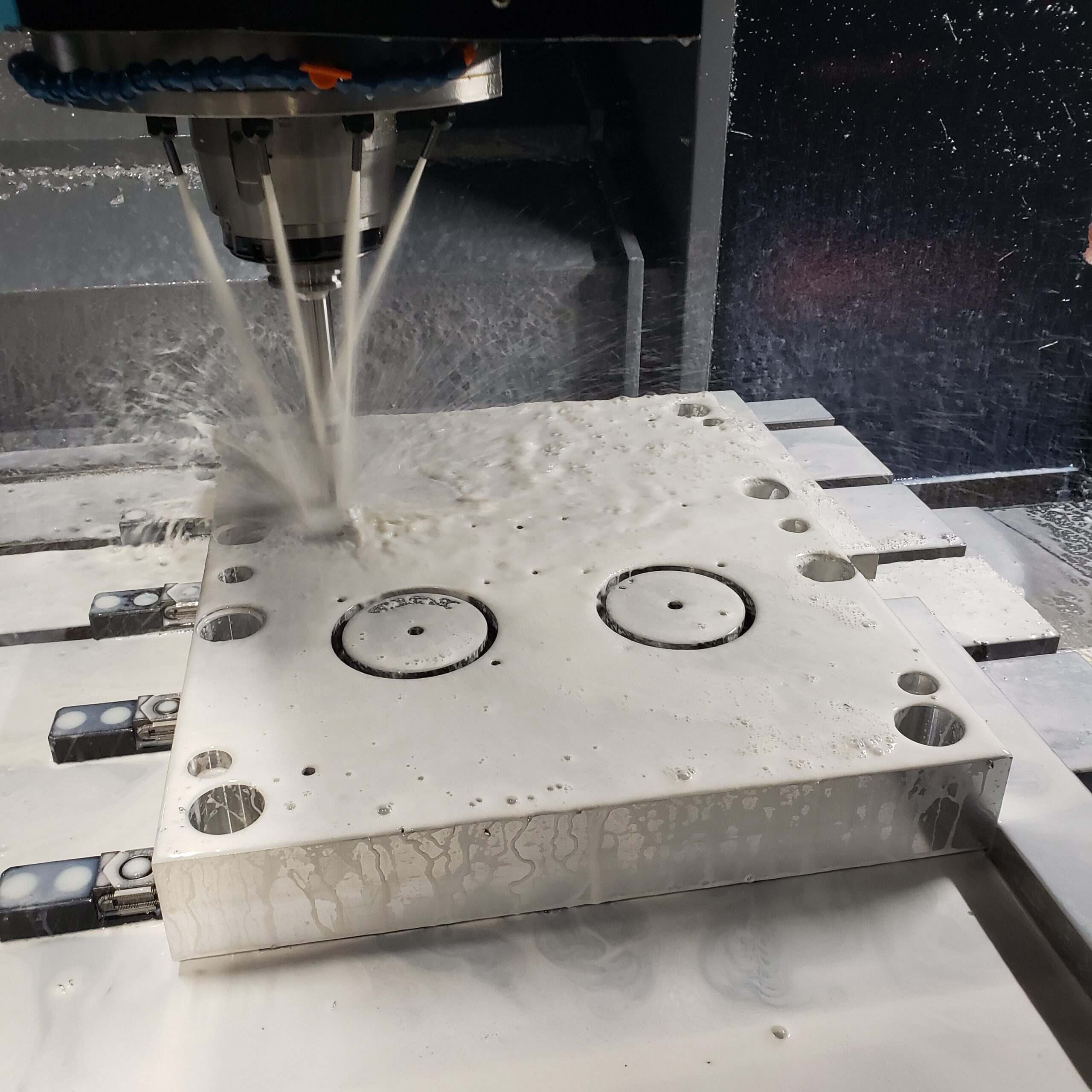

CNC machining uses advanced computer technology to cut complex and precise surface shapes into the mold materials. Our mold designers create a 3D model with the required mechanical dimensions and shapes of the mold details using CAD software. Final mold designs that are ready for machining can take one or two weeks to complete.

The 3D CAD models within the final mold design are then used within our CAM software. Our CAM programmers can tell the software how to machine the raw metal into the final mold shape and the software creates the commands to execute in our CNC machines.

Whatever type of plastic injection mold you need, we understand that your injection mold purchase will become a significant asset to your business. For that reason, we warranty the production life of molds we build for our customers for the life of their production requirements.

We hope this information helps you better understand plastic injection mold construction and their cost. Remember the quality of your custom plastic parts will first depend on the quality of your mold. Let us quote your next injection molding project and we will work closely with you to make your project a success!